Printing Differences

By Kyle Knott, Senior Account Manager

Designing a custom printed bag can be a difficult task. A common question posed to me is, “What is more popular, matte finish or glossy”? If you stroll down your neighborhood grocery store aisle you’ll notice a plethora of different looking bags. While the bag styles might change, in the world of printing there are only a few different types of finishes to utilize. And while different bag styles can have a big impact on consumer perception, what your bag looks like on the outside tells potential customer a lot about what might be on the inside of the bag.

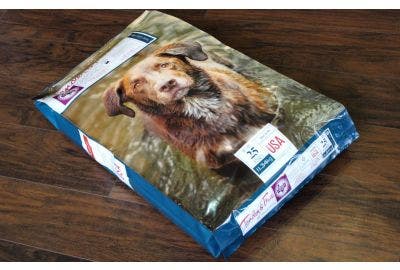

Glossy print (aka shiny) is the most common print format. This is for several reasons but the most important is, ITS SHINY! It reflects light better and acts as a magnet to the eye. All printed bags start off shiny. And while this format has been around the longest, it has its fan base. Often, a shiny bag can help artwork “pop” off the bag better. In the pet food segment, glossy print was king for several years. You might notice that most large package formats (12lb-40lbs range) are usually glossy. This has less to do with consumer appeal and is more about functionality, but I’ll get into that a little bit later. Companies are constantly trying to out-do the competition and one recent trend in printed packaging has found a solid foot-hold in the pet food segment. Enter, matte printing.

Matte finish has been around for quite some time and used heavily in several specialty food categories. And although it has taken awhile to catch in the pet food world, matte finish is becoming more and more popular. Matte finish is popular for a couple of reasons. Most often, people want a way to soften the look of their bag and give the art work a more “homey” appeal. Matte coating is an easy process and typically will not add a lot of cost to the packaging. However, it is not without its limitations.

Matte finish is great for giving your bag a muted, understated look. But, it is not recommended for large bag formats. As I stated earlier, for the larger bag category (12lb-40lb) matte ink does not mix well with anti-skid. Thus, making larger bags that need to be stable on a pallet slippery and hard for co-packers to handle. Anti-skid is a clear-coat applied to bags that adds traction to the surface of the bags. Putting anti-skid over a matte layer will only make the bags shiny again. This is something to consider if you are having a manufacture produce and ship your food.

Things move fast in marketing. Everyone is trying to stay a step ahead of the competition. The latest trend taking hold in printed pet food packaging is a combination of the shiny and the matte finishes. Often called “registered matte”, the process involves starting with a shiny bag, adding a matte finish, then running the film through the press again and knocking out elements to make them shiny. Registered Matte finish gives you the best of both worlds, an understated look with eye catching elements specific to certain images or keywords. This is starting to pop up specifically in the small bag category but, I have a feeling that it will catch on in the bigger bags.

With so many options available for printing, it’s easy to get confused. Let Pacific Bag help develop that perfect package!

To learn more, visit our Pet Food Packaging page.